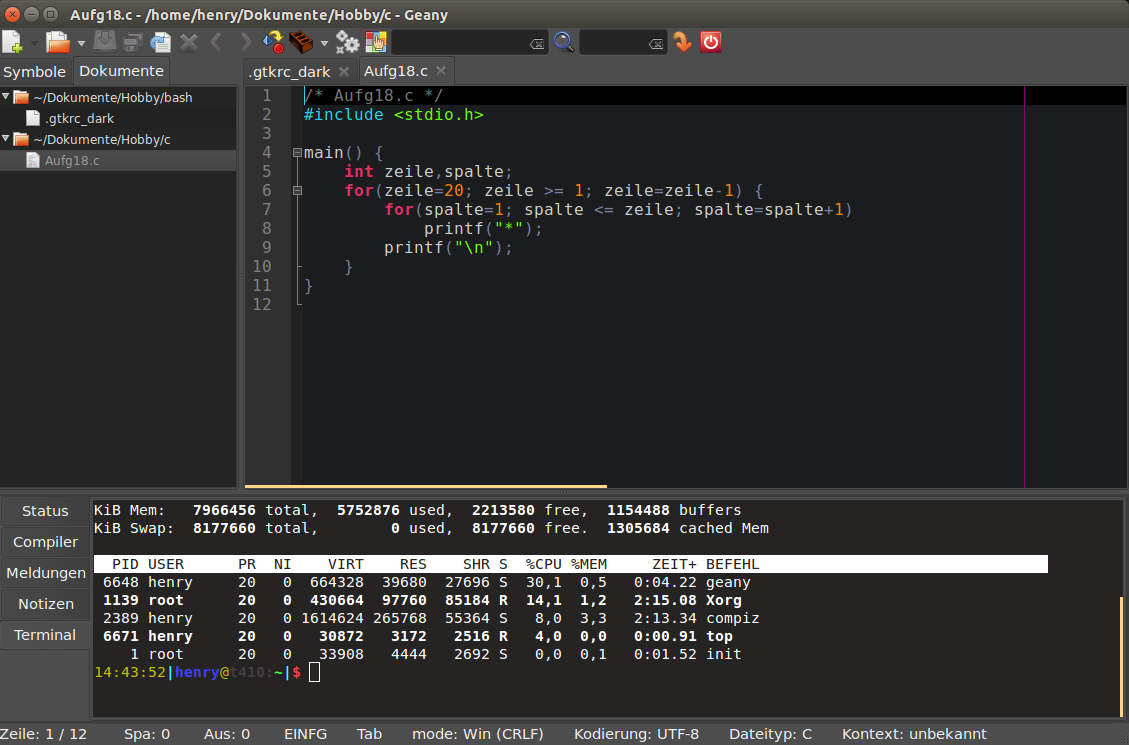

Geany dark Editor – configure an alternate dark color theme

general

My applications running under Ubuntu (As of today 1/2017 Version 14.10) with the window manager Unity and the Ubuntu standard GTK + theme Ambiance.

It is possible to select different styles in Unity, but the dark themes are looking not so nice across all applications.

Especially with the Internet browsers, I think dark themes are not suitable.

However, it is possible to start applications with individual selected ‘color’ themes.

In order to let geany look as shown in the picture further below, I proceeded as follows.

step by step

- install geany, if not already present -> sudo apt-get install geany

editor internal

- If there should be no color themes available in geany, download them here: https://github.com/geany/geany-themes/

- copy the folder colorschemes into ~/.config/geany/

- now you can choose in geany from View -> Editor -> Color Themes – Color Themes your preferred Theme

I use ‘raspberry’.

Editor outside area

As described in http://www.henrykoch.de/de/eclipse-programmierumgebung-dunkel-machen, I build on an existing dark GTK+ theme and have modified this for me.

The following informations I stored as file .gtkrc_dark in ~/home/…/ (choose a convinient place for you)

gtk-color-scheme = "base_color:#252525\nfg_color:#f0f0f0\ntooltip_fg_color:#252525\nselected_bg_color:#FFD587\nselected_fg_color:#252525\ntext_color:#dadada\nbg_color:#4d4d4d\ntooltip_bg_color:#FFA500\nlink_color:#494949" style "gtkcompact" { font_name="Sans 11" GtkButton::default_border={0,0,0,0} GtkButton::default_outside_border={0,0,0,0} GtkButtonBox::child_min_width=0 GtkButtonBox::child_min_heigth=0 GtkButtonBox::child_internal_pad_x=0 GtkButtonBox::child_internal_pad_y=0 GtkMenu::vertical-padding=1 GtkMenuBar::internal_padding=0 GtkMenuItem::horizontal_padding=4 GtkToolbar::internal-padding=0 GtkToolbar::space-size=0 GtkOptionMenu::indicator_size=0 GtkOptionMenu::indicator_spacing=0 GtkPaned::handle_size=4 GtkRange::trough_border=0 GtkRange::stepper_spacing=0 GtkScale::value_spacing=0 GtkScrolledWindow::scrollbar_spacing=0 GtkExpander::expander_size=10 GtkExpander::expander_spacing=0 GtkTreeView::vertical-separator=0 GtkTreeView::horizontal-separator=0 GtkTreeView::expander-size=8 GtkTreeView::fixed-height-mode=TRUE GtkWidget::focus_padding=0 #################### # Color Definitions #################### bg[NORMAL]= @bg_color bg[PRELIGHT] = shade (1.02, @bg_color) bg[SELECTED] = @selected_bg_color bg[INSENSITIVE] = shade (0.95, @bg_color) bg[ACTIVE]= shade (0.9, @bg_color) fg[NORMAL]= @fg_color fg[PRELIGHT] = @fg_color fg[SELECTED] = @selected_fg_color fg[INSENSITIVE] = darker (@bg_color) fg[ACTIVE]= @fg_color text[NORMAL] = @text_color text[PRELIGHT]= @text_color text[SELECTED]= @selected_fg_color text[INSENSITIVE] = shade (0.8, @bg_color) text[ACTIVE] = darker (@text_color) base[NORMAL] = @base_color base[PRELIGHT]= shade (0.98, @bg_color) base[SELECTED]= @selected_bg_color base[INSENSITIVE] = shade (0.97, @bg_color) base[ACTIVE] = shade (0.94, @bg_color) } class "GtkWidget" style "gtkcompact" style "gtkcompactextra" { xthickness=0 ythickness=0 } class "GtkButton" style "gtkcompactextra" class "GtkToolbar" style "gtkcompactextra" class "GtkPaned" style "gtkcompactextra"

To start, I still need a bash script:

#!/bin/sh export GTK2_RC_FILES="/home/.../.gtkrc_dark" geany $1 env --unset=GTK2_RC_FILES

In addition, I have built a small dark geany logo and also stored under /home/…/ . (the 3 files as zip file geanydarkfiles.zip)

The last action must be performed with root privileges: sudo gedit /usr/share/applications/geany.desktop

Adjust the following two entries:

Exec=/home/.../geany.sh %F Icon=/home/.../geany.xpm

Now Geany can always be called in dark, without having to start it from a console so it becomes dark.